2025-08-05

In modern heating, ventilation, and air conditioning (HVAC) systems, efficient temperature control is vital for comfort, energy savings, and equipment longevity. One key component that enhances system performance—especially in automotive and industrial HVAC applications—is the auto intercooler. While intercoolers are more commonly known in automotive turbocharged engines, their concept and technology have found valuable applications in HVAC systems as well. But what exactly is an HVAC auto intercooler, and how does it contribute to the system’s overall performance?

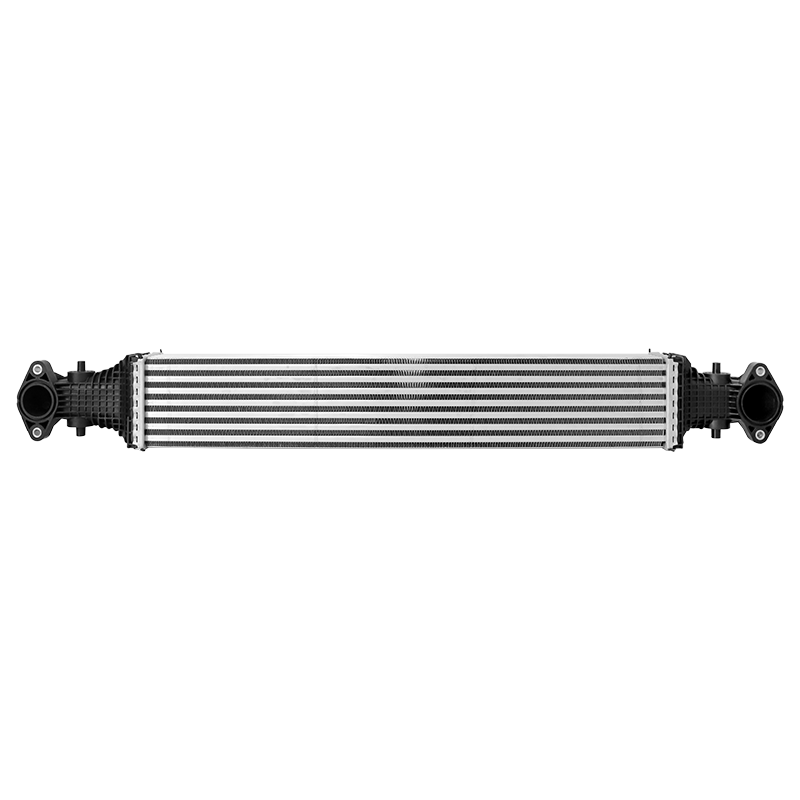

1. Definition of HVAC Auto Intercooler

An HVAC auto intercooler is a specialized heat exchanger integrated within an HVAC system designed to cool compressed air or refrigerant between stages of compression. It “intercools” the air or fluid, reducing its temperature before it proceeds to the next stage or system component.

In automotive contexts, “auto” typically refers to automatic or automotive applications, but in HVAC, it can also imply automated or selfregulating intercoolers that optimize performance without manual intervention.

2. Why is Intercooling Needed in HVAC Systems?

Many HVAC systems, especially those using compressors such as in chillers, refrigeration units, or automotive air conditioning, compress air or refrigerant as part of their operation. Compression raises the temperature of the gas or fluid, which can reduce system efficiency and strain components.

Intercooling provides several benefits:

Reduces Air Temperature: Lowering the temperature of compressed air or refrigerant increases efficiency and reduces the work required in subsequent compression stages.

Increases System Efficiency: Cooler air or refrigerant improves heat exchange performance, reducing energy consumption.

Protects Components: High temperatures can damage compressors, valves, and seals. Intercooling helps maintain safer operating temperatures.

Improves Air Quality: In some HVAC airhandling units, intercooling can reduce humidity and remove contaminants by cooling the air between stages.

3. How Does an HVAC Auto Intercooler Work?

The working principle of an HVAC auto intercooler is straightforward:

Compression Stage: Air or refrigerant enters a compressor, where it is compressed and heated.

Intercooling Stage: The hot compressed air or refrigerant passes through the intercooler, which is a heat exchanger that transfers heat from the gas/fluid to a cooler medium (usually ambient air or cooling water).

Cooling Medium: The intercooler uses fins, coils, or plates to maximize heat dissipation to the environment or a cooling circuit.

Cooled Output: The cooled air or refrigerant then moves on to the next compression stage or to the condenser/evaporator components of the HVAC system.

An “auto” intercooler often includes sensors and control systems that automatically regulate cooling flow, fan speed, or valve positions based on temperature and pressure data, optimizing intercooling performance dynamically.

4. Types of HVAC Auto Intercoolers

There are several types of intercoolers used in HVAC systems, based on the cooling medium and design:

AirtoAir Intercoolers: Use ambient air to cool the compressed air/refrigerant. Common in automotive air conditioning and some industrial units.

AirtoWater Intercoolers: Use chilled water or coolant flowing through coils to absorb heat. Typically found in large commercial or industrial HVAC systems.

Plate Heat Exchangers: Compact, efficient heat exchangers often used in automated systems.

Shell and Tube Intercoolers: Traditional design used in heavyduty applications.

The “auto” aspect usually refers to builtin automation controls for temperature regulation.

5. Applications of HVAC Auto Intercoolers

The HVAC auto intercooler plays a critical role in several applications:

Automotive HVAC Systems: Turbocharged vehicles use intercoolers to cool compressed air before it enters the engine, improving efficiency. Similarly, automotive air conditioning systems use intercooling technology to enhance cooling.

Industrial Chillers: Large chillers employ intercoolers to improve refrigerant cycle efficiency.

Commercial HVAC Systems: Intercoolers improve the performance of multistage compressors used in large building climate control.

Refrigeration Units: Help reduce compressor discharge temperatures for longer component life.

Air Handling Units (AHUs): Some advanced AHUs integrate intercooling stages for air quality improvement and humidity control.

6. Benefits of Using HVAC Auto Intercoolers

Energy Efficiency: By lowering the temperature of compressed gases, intercoolers reduce the load on compressors, saving energy.

Extended Equipment Life: Cooler operation reduces wear on compressors and other components.

Improved System Capacity: Cooler compressed air allows the system to handle higher volumes or pressures without overheating.

Better Comfort Control: Enhanced temperature and humidity management lead to better indoor air quality and comfort.

Automation and Smart Control: Auto intercoolers adapt to varying operating conditions, optimizing performance without manual intervention.

7. Challenges and Considerations

Initial Cost: Incorporating intercoolers adds to system complexity and upfront cost.

Maintenance: Intercoolers need regular cleaning and inspection to maintain heat exchange efficiency.

Space Requirements: Depending on design, intercoolers may require additional space within HVAC installations.

Compatibility: The intercooler must be matched to the specific compressor and system parameters for best performance.

An HVAC auto intercooler is a vital component that enhances the performance and reliability of HVAC systems by cooling compressed air or refrigerant between stages. Through efficient heat exchange and automated control, these intercoolers improve energy efficiency, extend equipment life, and maintain optimal operating conditions. Whether in automotive air conditioning, industrial chillers, or commercial HVAC installations, auto intercoolers contribute significantly to modern cooling and heating technologies.