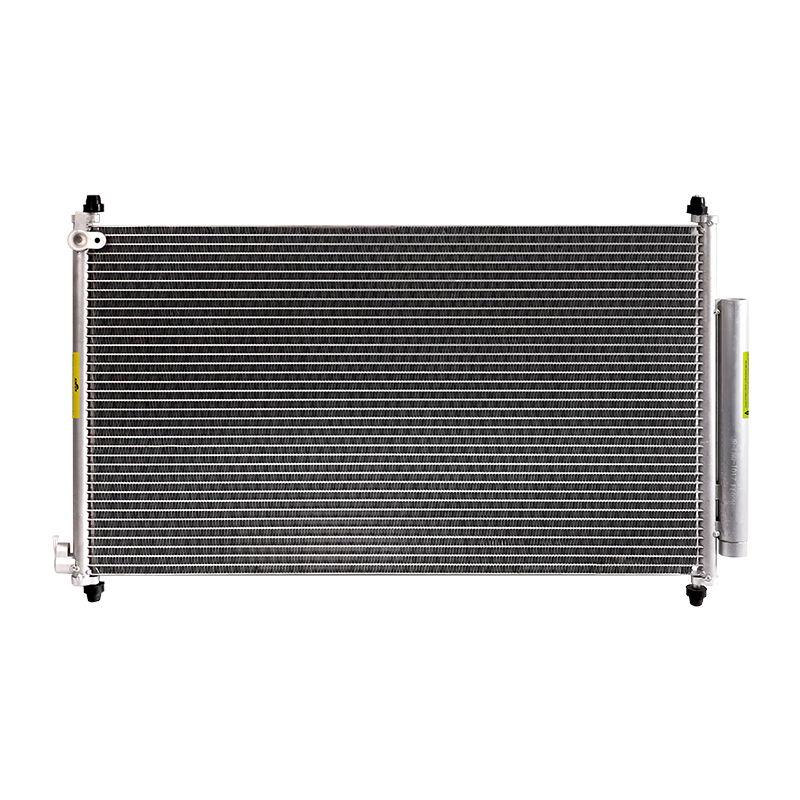

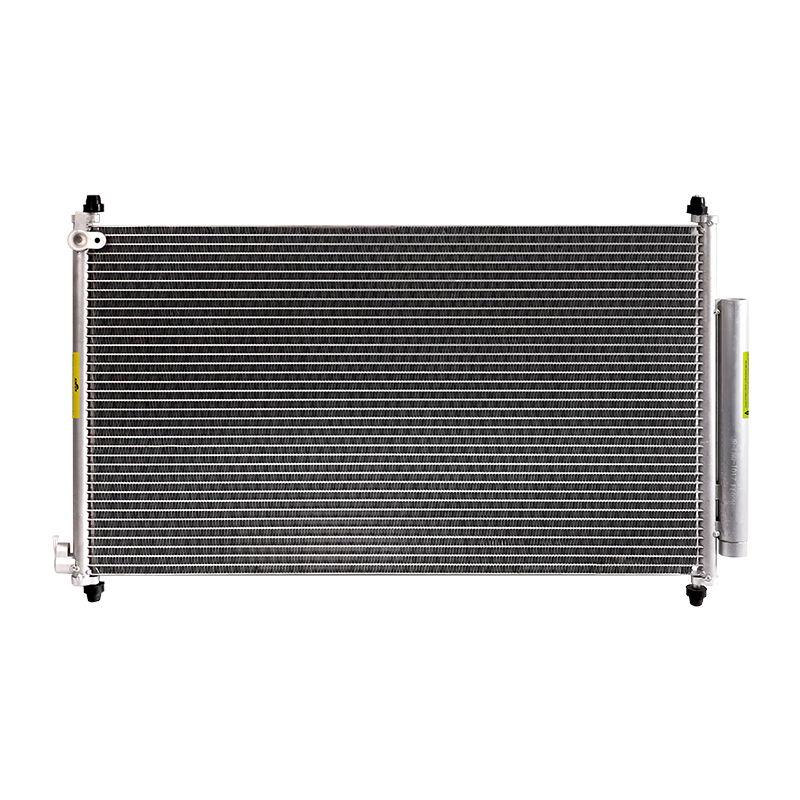

An HVAC auto condenser is one of the most critical components in a vehicle’s air conditioning system. Although often overlooked by car owners, it plays a fundamental role in keeping the cabin cool and maintaining the efficiency of the air conditioning system. Understanding its function and operation is essential for anyone interested in automotive maintenance, HVAC technology, or vehicle performance.

1. Core Function of an Auto Condenser

The primary function of an HVAC auto condenser is to convert high-pressure refrigerant gas from the compressor into a liquid form. This process is essential in the air conditioning cycle because the refrigerant must be in liquid form before it can evaporate in the evaporator coil and absorb heat from the cabin air.

- Heat Rejection: The condenser removes heat from the refrigerant by transferring it to the outside air, usually via a radiator-like coil and cooling fins.

- Pressure Regulation: It maintains the necessary pressure difference in the system, enabling efficient flow of refrigerant from the compressor to the expansion valve or orifice tube.

- Supporting System Efficiency: By effectively rejecting heat, the condenser ensures that the evaporator receives cold, low-pressure refrigerant, which improves cooling performance and energy efficiency.

2. How the Auto Condenser Works

The HVAC auto condenser works as part of a closed-loop system that includes the compressor, evaporator, receiver/dryer, expansion valve, and associated piping. The working principle is as follows:

- High-Pressure Gas Entry: The refrigerant leaves the compressor as a high-pressure, high-temperature gas.

- Heat Dissipation: As the refrigerant flows through the condenser coils, heat is transferred to the air passing over the fins. This can be assisted by the vehicle’s radiator fan or by the movement of the vehicle itself.

- Phase Change: Cooling causes the refrigerant to condense from a gas into a high-pressure liquid.

- Flow to Expansion Device: The liquid refrigerant is then directed to the receiver/dryer or accumulator and the expansion device, ready to evaporate and absorb heat inside the cabin.

This cycle repeats continuously when the air conditioning system is running, maintaining a comfortable cabin temperature.

3. Types of Automotive Condensers

Automotive condensers come in several types, designed to suit different vehicles and system requirements:

- Tube-and-Fin Condensers: Traditional design with copper or aluminum tubes and fins for heat dissipation. Simple, reliable, and cost-effective.

- Plate-Fin Condensers: Compact and lightweight, often used in modern vehicles for improved efficiency.

- Parallel Flow Condensers: Allow refrigerant to flow through multiple channels simultaneously, enhancing heat transfer and system efficiency.

Each type affects how quickly heat is rejected and how efficiently the air conditioning system operates.

4. Importance of the Auto Condenser

The condenser is not just a passive component—it directly impacts vehicle performance and comfort:

- Cabin Comfort: A fully functional condenser ensures that the air coming from the vents is cold, even in hot weather.

- Compressor Protection: By effectively converting refrigerant gas into liquid, the condenser prevents the compressor from overworking, reducing wear and prolonging lifespan.

- Fuel Efficiency: Efficient heat rejection reduces the workload on the compressor and the engine, slightly improving fuel economy.

- System Longevity: Consistent cooling and proper pressure maintenance prevent leaks, corrosion, and system failures.

5. Common Issues and Maintenance

Like any automotive component, condensers can experience problems if not properly maintained:

- Clogging: Dust, dirt, and debris can accumulate on the condenser fins, reducing airflow and heat dissipation.

- Leaks: Small punctures or cracks allow refrigerant to escape, reducing cooling efficiency.

- Corrosion: Exposure to road salt and moisture can corrode the aluminum or copper, weakening the condenser.

- Physical Damage: Stones or road debris can damage fins or tubes, reducing heat transfer.

Maintenance Tips:

- Regularly clean the condenser surface using compressed air or a gentle stream of water.

- Check for signs of leaks and corrosion.

- Ensure the radiator fan operates correctly to maintain airflow.

- Replace the condenser if it is severely damaged or leaking, as this can compromise the entire air conditioning system.

6. Conclusion

An HVAC auto condenser is a vital component in a vehicle’s air conditioning system, responsible for transforming high-pressure refrigerant gas into liquid and rejecting heat to the outside environment. Its proper function ensures cabin comfort, protects the compressor, enhances fuel efficiency, and extends the life of the air conditioning system.

Understanding the role of the condenser helps drivers and technicians maintain optimal system performance. Regular inspection, cleaning, and timely replacement when necessary ensure that the air conditioning system remains reliable, efficient, and capable of providing a cool, comfortable environment even in extreme weather conditions.