Hangzhou Golden Sun Auto Parts (Kinfor Group) Celebrates Dual Milestones at Shanghai Automechanika 2024

Hangzhou Golden Sun Auto Parts (Kinfor Group) Celebrates Dual Milestones at Shanghai Automechanika 2024

Dec 02, 2024

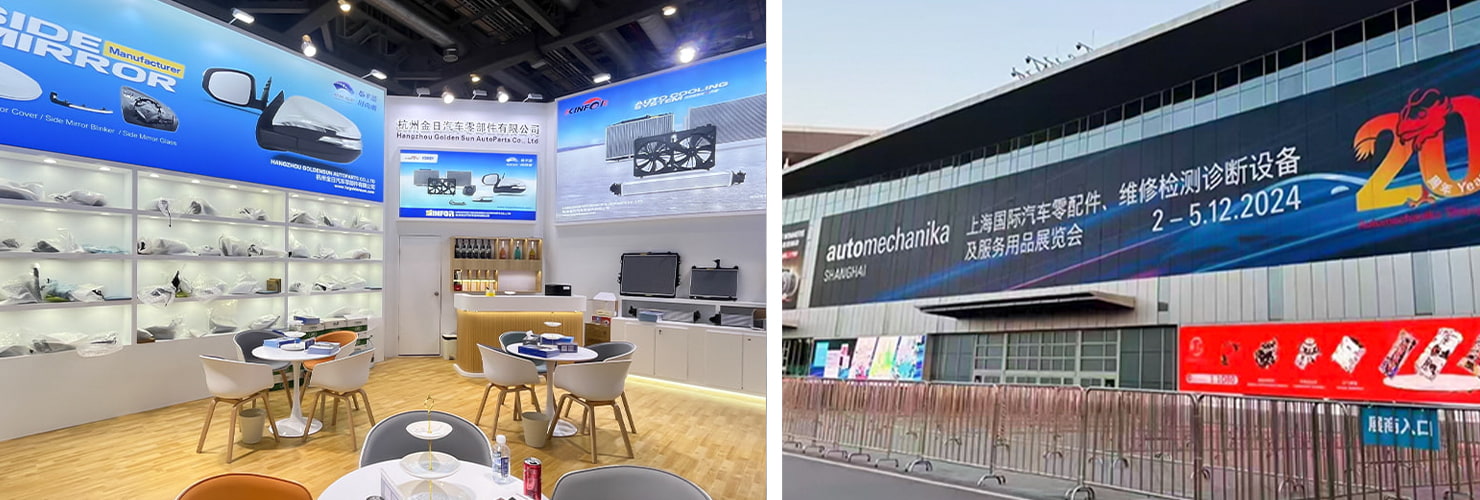

The year 2024 marked a momentous occasion for both Hangzhou Golden Sun Auto Parts (Kinfor Group) and Shanghai Automechanika, as both celebrated their 20th anniversary. The milestone event provided the golden stage for Kinfor Group to showcase its legacy of innovation, quality, and customer satisfaction through its dual booth exhibits, leaving a lasting impression on attendees at one of the world’s largest automotive trade fairs.

Kinfor Group’s participation in Shanghai Automechanika 2024 was amplified by the significance of its 20-year journey in the global automotive parts industry. The company’s two meticulously designed booths reflected its evolution and adaptability over the past two decades, catering to different facets of the automotive industry:

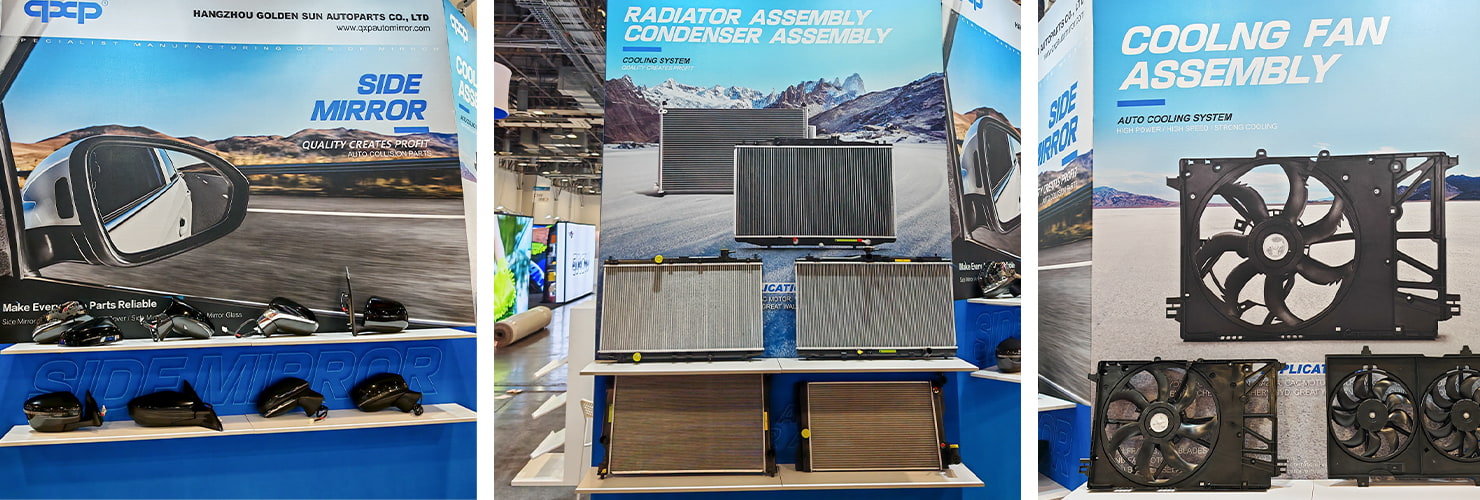

Core Products and Technology Booth: This booth highlighted Kinfor Group’s flagship products, including auto mirrors, radiators, electric fans, and condensers. With an interactive display featuring live demonstrations, visitors were able to see how these components are built to meet high industry standards. Data from the company’s archives showed that Kinfor has successfully supplied over 50 million units of radiators and 30 million units of auto mirrors globally since its founding.

Vehicle Modification and Accessories Booth: The second booth catered to the rising interest in vehicle customization, showcasing accessories such as tonneau covers, fender flares, mud flaps, and floor mats. The booth featured an innovative display that allowed attendees to visualize how these products could transform vehicles for both aesthetic and functional purposes. Statistics presented at the booth revealed that demand for vehicle accessories has grown by 15% annually in the Chinese market alone, with Kinfor Group capturing a significant portion of this growth over the past decade.

The 20th edition of Shanghai Automechanika also highlighted the exponential growth of the automotive industry. The 2024 show attracted over 5,000 exhibitors from 40 countries and welcomed more than 120,000 visitors. As one of the original participants of the event since its inception, Kinfor Group proudly celebrated its shared growth with the expo, reflecting on its role in shaping the industry over two decades.

At Shanghai Automechanika 2024, Kinfor Group showcased its cutting-edge components designed to enhance vehicle performance, safety, and durability:

Auto Mirrors: Trusted by manufacturers globally, Kinfor’s sub-brand qxp mirrors are designed for exceptional clarity and long-lasting durability, with over 99.99% customer satisfaction based on surveys conducted in 2023.

Radiators: Kinfor’s radiators ensure outstanding engine performance and longevity, boasting a defect rate of less than 0.1% across millions of units sold worldwide.

Electric Fans: Designed to improve energy efficiency, Kinfor’s electric fans contribute to reducing fuel consumption by up to 5%.

Condensers: With high performance and robust construction, Kinfor’s condensers are part of over 10 million vehicles worldwide, ensuring comfort and reliability in diverse climates.

The dedicated booth for vehicle modification and accessories highlighted Kinfor Group’s innovative approach to the growing customization market. This segment showcased:

Tonneau Covers: Lightweight, durable, and weather-resistant, Kinfor’s tonneau covers have been installed on over 2 million pickup trucks globally.

Fenders: Gold Ford's mudguards, which offer both protection and style, saw a 25% year-over-year increase in sales, reflecting their growing popularity among off-road enthusiasts.

Mud Flaps and Floor Mats: Engineered for durability, these accessories combine functionality and design, contributing to a 30% revenue growth in Kinfor’s accessories division over the past five years.

The stand highlights Kinfolk Group's ability to meet the needs of a diverse range of customers, positioning itself as a creator of customized market leaders while maintaining its core focus on quality and reliability.

With over 200 global distribution partners and a presence in more than 80 countries, Kinfor Group used Shanghai Automechanika 2024 as a platform to strengthen existing relationships and explore new opportunities. The event facilitated high-level discussions with potential clients from Europe, the Americas, and Southeast Asia, reflecting Kinfor’s commitment to expanding its market share in emerging regions.

Celebrating its 20th anniversary, Kinfor Group reflected on its journey from a local manufacturer in Hangzhou to a globally recognized name in the automotive parts industry. Since 2004, the company has achieved:

A production capacity exceeding 10 million units annually across its product range.

Export growth rates averaging 35% per year, contributing to its reputation as a trusted supplier in key markets such as North America, Europe, and the Middle East.

Recognition through multiple awards for quality and innovation, solidifying its position as an industry leader.

Hangzhou Golden Sun Auto Parts (Kinfor Group) marked its 20th anniversary in style at Shanghai Automechanika 2024, showcasing its evolution, innovation, and customer-centric approach with its dual booth presentation. As Shanghai Automechanika celebrated two decades of driving the global automotive industry forward, Kinfor Group stood as a testament to the progress and potential that the industry embodies.

With a strong focus on product excellence, sustainability and market expansion, the Kinfolk Group is expected to continue its success over the next 20 years and beyond, reinforcing its position as a trusted champion in the global automotive spare parts industry.

Hangzhou Golden Sun Auto Parts (Kinfor Group) Shines with Dual Booths at AAPEX 2024

Hangzhou Golden Sun Auto Parts (Kinfor Group) Shines with Dual Booths at AAPEX 2024

Nov 05, 2024

The Automotive Aftermarket Products Expo (AAPEX), held annually in Las Vegas, Nevada, is one of the automotive aftermarket industry's prestigious trade shows in the world. The 2024 edition brought together pioneering manufacturers, distributors, and innovators from around the globe, offering a comprehensive platform for showcasing cutting-edge automotive solutions and fostering meaningful industry connections. Among the standout participants was Hangzhou Golden Sun Auto Parts (Kinfor Group), which made a memorable impression with its two uniquely designed booths that captured the attention of attendees and industry professionals alike.

This year, Kinfor Group went above and beyond with two special decoration booths that served as focal points for their participation at AAPEX. Strategically located in high-traffic areas of the expo, the booths were designed to not only showcase the company’s diverse range of products but also create an immersive experience that highlighted its commitment to quality, innovation, and customer engagement.

At AAPEX 2024, Kinfor Group displayed its flagship products designed to enhance vehicle performance and ensure safety and durability:

Automotive mirrors: The mirrors from qxp, a sub-brand of the Kinfor Group, offer outstanding visibility and durability and meet high standards of clarity and safety, making them ideal for all types of vehicles.

Radiators: With efficient heat dissipation and robust construction, Kinfor’s radiators ensure vehicles run smoothly even under challenging conditions.

Electric Fans: Designed for outstanding cooling performance, Kinfor's electric fans provide energy-efficient solutions that improve engine efficiency and reduce emissions.

Condensers: Kinfor condensers are designed to provide outstanding HVAC system performance, ensuring comfort and reliability in any climate.

These products reflected Kinfor Group’s dedication to quality and innovation, attracting significant interest from attendees, distributors, and potential partners.

One of Kinfor Group’s dual booths was specially designed to cater to the growing interest in vehicle modification and accessories. This booth featured a wide range of products aimed at enhancing vehicle aesthetics and functionality, including tonneau covers, fender flares, mud flaps, and floor mats. The booth’s vibrant design and interactive displays highlighted how these accessories not only improve the look of a vehicle but also provide practical benefits such as protection from dirt, debris, and harsh weather conditions. Visitors had the opportunity to explore various customization options and see how Kinfor’s high-quality accessories could transform vehicles to meet individual preferences and lifestyle needs.

This focus on vehicle modification and accessories demonstrated Kinfor Group’s ability to meet the diverse demands of automotive enthusiasts and professionals, further establishing its versatility and customer-centric approach in the aftermarket industry.

The dual booths provided a dynamic setting for Kinfor Group to engage with a diverse audience, including distributors, buyers, and industry professionals. The vibrant and inviting design of the booths drew a steady stream of visitors, creating ample opportunities for networking, knowledge sharing, and business development.

The company’s representatives also participated in industry discussions, gaining valuable insights into emerging trends and customer needs in the North American automotive aftermarket. Kinfor Group leveraged this opportunity to strengthen existing partnerships and forge new ones, solidifying its presence in the region’s competitive market.

AAPEX 2024 marked a significant milestone for Kinfor Group as it continued to expand its reach in the North American automotive market. The company’s investment in two special decoration booths underscored its commitment to creating impactful brand experiences and delivering exceptional value to its customers and partners.

By blending innovation, sustainability, and a global outlook, Kinfor Group demonstrated its readiness to meet the evolving demands of the automotive industry. The success of its participation at AAPEX further reaffirmed its position as a global pioneering in automotive parts manufacturing.

Hangzhou Golden Sun Auto Parts (Kinfor Group) made a lasting impression at AAPEX 2024, thanks to its two meticulously designed booths that captured the essence of its innovation, quality, and global reach. By showcasing its advanced product offerings and engaging directly with industry leaders, the company strengthened its reputation as a trusted supplier and innovator in the automotive aftermarket.

With its continued focus on innovation, sustainability, and customer satisfaction, Kinfor Group is poised to further expand its footprint in North America and beyond, solidifying its role as a key player in shaping the future of the global automotive industry.

Hangzhou Golden Sun Auto Parts (Kinfor Group) at Expomecánica Perú 2024: Strengthening Ties with Latin America

Hangzhou Golden Sun Auto Parts (Kinfor Group) at Expomecánica Perú 2024: Strengthening Ties with Latin America

May 17, 2024

Hangzhou Golden Sun Auto Parts (Kinfor Group) at Expomecánica Perú 2024: Strengthening Ties with Latin America

Expomecánica Perú 2024, one of Latin America's premier automotive trade shows, took place in Lima, Peru, gathering thousands of automotive professionals, industry experts, and global manufacturers. The event served as a significant platform for showcasing the latest innovations in automotive parts, equipment, tools, and services, bringing together suppliers, manufacturers, and business leaders to foster collaboration and growth in the region’s automotive sector.

Hangzhou Golden Sun Auto Parts (Kinfor Group), a prominent player in the global automotive parts industry, made a notable appearance at Expomecánica Perú 2024, reinforcing its commitment to expanding its presence in the Latin American market. As a key supplier of high-quality automotive components, Kinfor Group’s participation highlighted its dedication to providing reliable and advanced automotive solutions tailored to the diverse needs of the regional market.

A Global Leader in Automotive Parts

Founded in Hangzhou, China, Hangzhou Golden Sun Auto Parts Co., Ltd (Golden Fortune Group) is a renowned global manufacturer of automotive parts. With decades of experience, the company has built a solid reputation for delivering high-performance products, including auto mirrors, radiators, electric fans, and condensers. Kinfor Group serves both domestic and international markets, offering products that meet rigorous quality standards while maintaining a focus on innovation and customer satisfaction.

Showcasing Advanced Automotive Solutions at Expomecánica Perú

At Expomecánica Perú 2024, Kinfor Group presented its latest lineup of automotive components, designed to meet the demands of modern vehicles and address the specific needs of the Peruvian and broader Latin American markets. The company’s exhibit highlighted key products, including:

Auto Mirrors: Known for their durability and exceptional clarity, qxp auto mirrors provide advantageous visibility for enhanced safety, a critical feature for vehicles in Latin America’s diverse road conditions.

Radiators: Kinfor’s radiators offer efficient heat management, helping vehicles maintain prime mover engine temperatures even in challenging environments, and ensuring reliability and longevity.

Electric Fans: Designed to provide prime mover cooling while minimizing energy consumption, Kinfor's electric fans are a must-have in modern automobiles, improving engine performance and efficiency.

Condensers: As part of the HVAC system, Kinfor’s condensers ensure that vehicles’ air conditioning systems work efficiently, offering comfort to drivers and passengers in the region’s varying climates.

These products reflect Kinfor Group’s commitment to providing high-quality, technologically advanced solutions that improve vehicle performance, safety, and comfort. The company’s focus on continuous innovation and quality control has made it a trusted name in the automotive industry.

Expanding Footprint in Latin America

Expomecánica Perú was the ideal stage for Kinfor Group to strengthen its ties with the Latin American market. The event attracted key stakeholders from Peru, Colombia, Chile, Ecuador, and other countries in the region, offering Kinfor Group the chance to engage with automotive distributors, service providers, and fleet operators. Peru’s growing automotive market, coupled with an increasing demand for quality spare parts and components, presents significant opportunities for Kinfor Group to expand its business in the region.

Kinfor Group's participation in Expomecánica Perú also underscored the company’s commitment to enhancing its regional presence. By interacting directly with local partners and customers, Kinfor was able to gain valuable insights into market trends, consumer preferences, and the specific requirements of Latin American customers. This interaction not only facilitated business opportunities but also laid the foundation for long-term relationships with local distributors and partners.

Networking and Building Strategic Partnerships

Expomecánica Perú 2024 provided Kinfor Group with a prime opportunity to network with key decision-makers, potential partners, and industry experts from the Latin American automotive sector. The event allowed Kinfor to showcase its products, engage in discussions about industry challenges, and explore new avenues for collaboration.

As Latin America’s automotive sector continues to grow, there is an increasing demand for high-quality auto parts. Kinfor Group’s advanced product offerings, coupled with its strong reputation for reliability and customer service, position the company to play a significant role in fulfilling the needs of the region’s expanding automotive industry.

Automechanika Astana 2024: A Premier Auto Parts Show in Kazakhstan

Automechanika Astana 2024: A Premier Auto Parts Show in Kazakhstan

Apr 17, 2024

Automechanika Astana 2024: A Premier Auto Parts Show in Kazakhstan

Automechanika Astana is one of the largest and influential automotive trade fairs in Kazakhstan and Central Asia. Held in Astana (now known as Nur-Sultan), the capital city of Kazakhstan, this event attracts industry professionals from across the globe, showcasing the latest innovations in automotive parts, repair and maintenance, diagnostics, accessories, and more. It serves as a significant platform for manufacturers, suppliers, and service providers to exhibit their products and services, connect with potential customers, and explore business opportunities in the region.

The 2024 edition of Automechanika Astana will feature hundreds of exhibitors, with a focus on the latest developments in automotive technologies, and cater to a diverse range of industry professionals, including distributors, fleet managers, garage owners, car service professionals, and vehicle manufacturers. The show is also a clearinghouse for business development and industry collaboration.

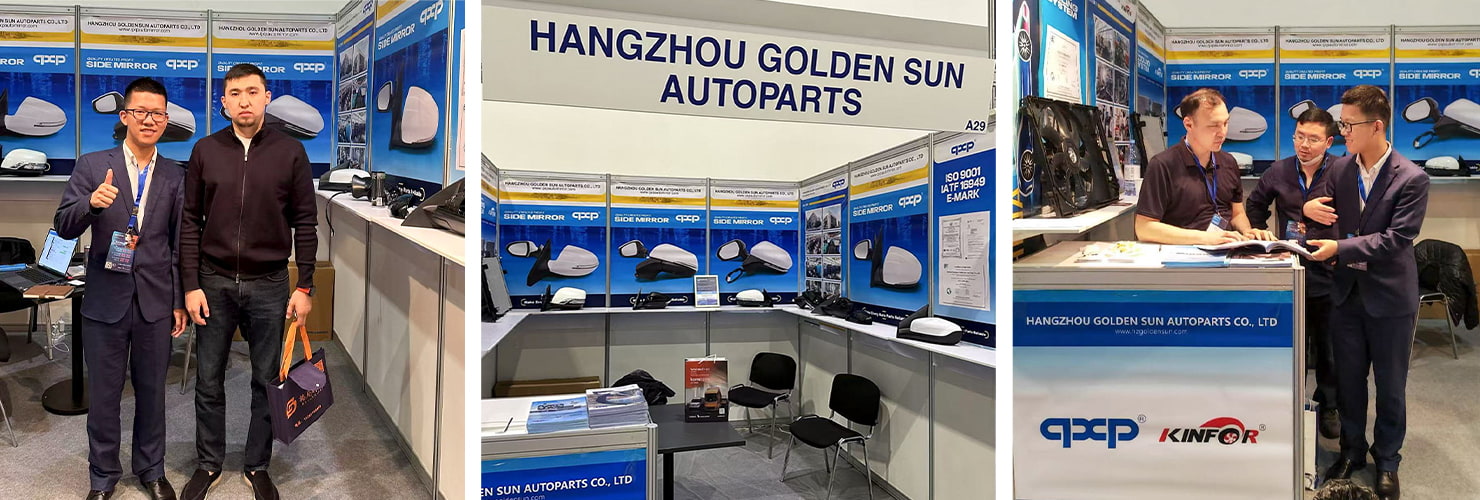

Hangzhou Golden Sun Auto Parts (Kinfor Group) at Automechanika Astana 2024

Hangzhou Golden Sun Automotive Parts Co., Ltd (Jinfo Group) has further strengthened its position as a pioneer in the global automotive parts industry by making a splash at the prestigious Astana International Auto Parts Expo 2024. As a key player in the auto parts sector, Kinfor Group’s participation in this high-profile trade fair showcases its commitment to expanding its footprint in Central Asia and providing top-quality automotive solutions to the rapidly growing regional market.

Hangzhou Golden Sun Auto Parts (Kinfor Group), founded in Hangzhou, China, is a renowned manufacturer of automotive parts and components. With decades of experience, the company has developed a strong reputation for producing high-quality products that meet the diverse needs of the automotive industry. Specializing in a wide range of parts, including auto mirrors, radiators, electric fans, and condensers, Kinfor Group has been a trusted supplier for both domestic and international markets.

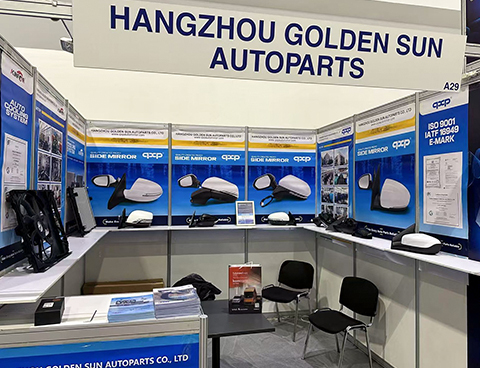

At Automechanika Astana 2024, Kinfor Group showcased its latest range of advanced automotive parts designed to enhance vehicle performance, safety, and durability. The company’s display featured innovative products such as:

Automotive Mirrors: Exp automotive mirrors are designed for outstanding visibility and durability, with best-in-class safety and performance that meets the rigorous standards of the automotive industry.

Radiators: Kinfor radiators focus on efficient cooling and heat management, with standing high temperatures to ensure engines run at optimum temperatures in demanding conditions.

Electric Fans: Kinfor’s electric fans are designed to improve engine cooling and reduce energy consumption, making them a vital component in modern vehicles that require efficient and sustainable cooling systems.

Condensers: Offering high-performance condensers that help regulate temperature and pressure within the vehicle’s HVAC system, Kinfor’s condensers contribute to improved cabin comfort and system efficiency.

Kinfor Group’s participation in Automechanika Astana 2024 underscored its dedication to innovation and product development. The company’s engineers and designers are constantly working to enhance the performance of their parts, utilizing the latest technological advancements in automotive manufacturing. Kinfor Group prides itself on maintaining high standards of quality, ensuring that each product not only meets but exceeds the expectations of customers.

Automechanika Astana 2024 offered Kinfor Group an outstanding opportunity to network with industry professionals, potential customers, and partners in the Central Asian automotive market. The event provided a platform to discuss the evolving needs of the region, explore new business opportunities, and build long-term partnerships with distributors, vehicle manufacturers, and service providers.

The automotive market in Kazakhstan and Central Asia is experiencing rapid growth, driven by increasing vehicle ownership, infrastructure development, and demand for high-quality auto parts. Kinfor Group’s presence at Automechanika Astana reflects its strategic focus on expanding its reach in these burgeoning markets. The event also enabled the company to gain valuable insights into regional market trends, consumer preferences, and potential areas for growth.

Jinfu Group's participation in Automechanika Astana 2024 underscored its position as a forward-thinking and customer-focused pioneer in the automotive components industry.By showcasing its innovative products, engaging with industry professionals, and exploring new business opportunities, Kinfor Group reaffirmed its commitment to delivering exceptional automotive solutions to the global market. As the automotive industry continues to evolve, Hangzhou Golden Sun Auto Parts (Kinfor Group) is poised to remain at the forefront of technological advancement and quality in automotive parts manufacturing.

With such successful participation in the 2024 Automechanika Astana, Kinfor Group is well-positioned to strengthen its presence in the Central Asian market and continue driving the future of automotive parts and technology.

Appearing at the 2023 Zhengzhou Exhibition, showing quality & strength

Appearing at the 2023 Zhengzhou Exhibition, showing quality & strength

Oct 31, 2023

Hangzhou Jinri Auto Parts Co., Ltd. has always been committed to providing customers with high-quality and high-performance parts products. This time, the company brought a series of the latest research and development products and technical achievements, fully demonstrating its innovation ability and professional level in the field of automotive parts.

At the exhibition site, Hangzhou Jinri's booth was crowded with people, attracting the attention of many visitors. The company's professional team patiently introduced the characteristics, advantages, and application scenarios of the products to customers, and had in-depth exchanges with them to jointly discuss industry development trends and market prospects.

Through this exhibition, Hangzhou Jinri Auto Parts Co., Ltd. not only demonstrated its strength and charm to the industry but also established connections with many potential customers and partners, laying a solid foundation for the company's future development.